In the rapidly evolving landscape of modern manufacturing, the demand for precision, efficiency, and customization has never been higher. Enter custom CNC milling services—an innovative solution that not only meets these demands but also revolutionizes the way businesses approach production.

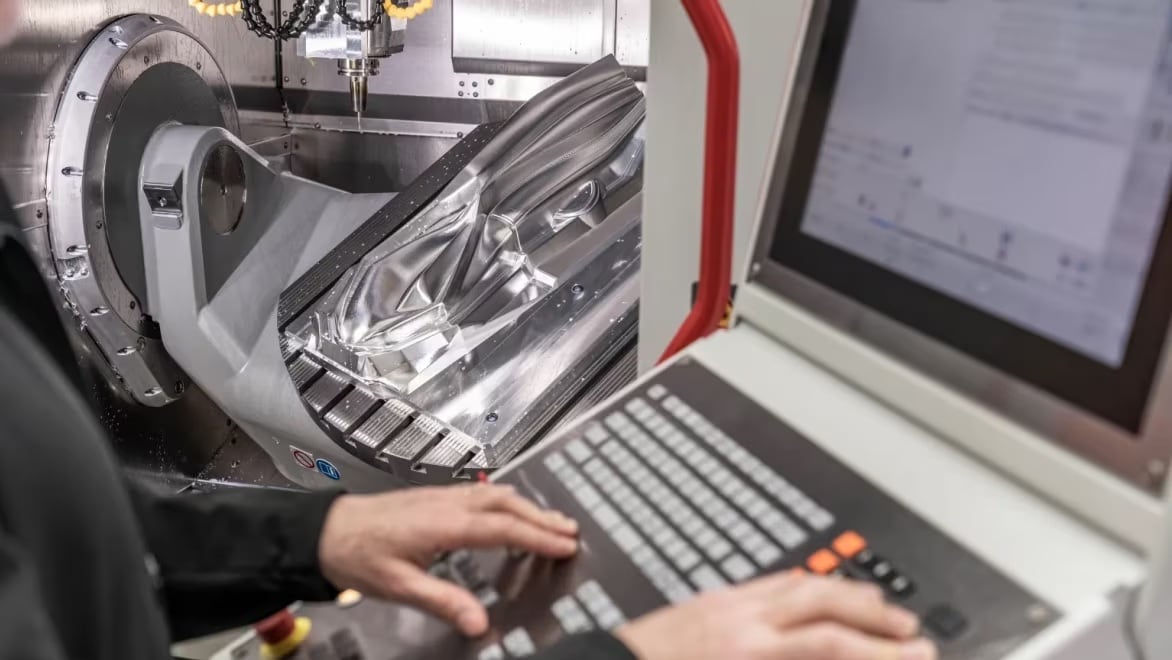

Unlike traditional methods, which often involve time-consuming adjustments and limitations to design capabilities, CNC milling allows for intricate customization tailored to specific project needs. Imagine a world where manufacturers can swiftly transform complex designs into tangible products, all while maintaining the highest standards of accuracy.

This paradigm shift is not just about enhancing production; it reflects a fundamental change in how manufacturers think about their processes and how they can adapt to the ever-changing marketplace. As we delve into the transformative impact of custom CNC milling services, we uncover why this technology is indeed a game changer for the future of manufacturing.

The Benefits of Custom CNC Milling Services

Custom cnc milling services revolutionize modern manufacturing by offering unparalleled precision and adaptability tailored to the unique needs of various industries. This bespoke approach allows companies to produce complex geometries and intricate designs that would otherwise be impossible or prohibitively expensive using traditional machining methods.

With the ability to rapidly prototype and iterate designs, manufacturers can significantly reduce lead times while simultaneously enhancing product performance and quality. Furthermore, the flexibility of CNC milling means that changes can be implemented swiftly, ensuring that businesses can respond to market demands with agility.

From aerospace to healthcare, the myriad applications of custom milling elevate manufacturing capabilities, enabling innovation and setting new standards of excellence.

Integration with CAD/CAM Technologies

The integration of CAD/CAM technologies with custom CNC milling services revolutionizes the landscape of modern manufacturing, bringing unparalleled precision and efficiency to the forefront. Imagine designing intricate components on a sophisticated software platform, where every dimension is meticulously accounted for, and then seamlessly transitioning that digital blueprint into the physical realm with a CNC machine capable of executing those designs with astonishing accuracy.

This synergy not only streamlines the production process but enables manufacturers to experiment with complex geometries and material combinations that were once thought impossible. Consequently, businesses can respond to market demands with agility, creating bespoke parts on-demand while minimizing waste and reducing lead times.

Ultimately, the marriage of CAD/CAM with CNC milling embodies a transformative shift, empowering engineers and designers to push the boundaries of innovation like never before.

The Impact of AI and Machine Learning

The advent of AI and machine learning has revolutionized the landscape of custom CNC milling services, marking a transformative shift in modern manufacturing. By harnessing predictive analytics, manufacturers can foresee potential failures and optimizing machine performance before they even happen.

This proactive approach not only reduces downtime but significantly enhances precision and efficiency. Imagine a scenario where intricate designs can be modeled and tested in virtual environments, reducing the need for physical prototypes.

Furthermore, AI-driven algorithms analyze vast amounts of data, allowing for real-time adjustments during milling processes. Such adaptive capabilities enable manufacturers to produce complex geometries that were once deemed impossible, all while maintaining a rapid turnaround time.

In this era of smart manufacturing, it’s clear that integrating AI and machine learning isn’t just an option; it’s becoming a vital cornerstone for thriving in a competitive marketplace.

Conclusion

In conclusion, custom CNC milling services represent a transformative force in the landscape of modern manufacturing. By offering unparalleled precision, flexibility, and efficiency, these services empower businesses to create complex components and prototypes tailored to their specific needs.

The ability to quickly adapt to changes, enhance product quality, and reduce lead times not only streamlines production processes but also fosters innovation across various industries. As technology continues to advance, embracing custom CNC milling will undoubtedly become a strategic advantage for manufacturers aiming to stay competitive in an increasingly demanding market.